| Electric | |

|---|

| Power Supply | 24 VAC/VDC, -20%/+15%

50/60 Hz,

reverse polarity protected |

|---|

|

| Power Consumption | 5 VA (0.2 A) w/ (1) remote sensor

connected |

|---|

|

| Sensor Performance | |

|---|

|

| Gas detected | Carbon monoxide (CO) |

|---|

|

| Sensor element | Electrochemical, diffusion |

|---|

|

| Range | Span field adjustable

from 0-200 to 0-300 ppm

via calibration,

0-250 ppm factory set |

|---|

|

| Stability & Resolution | ± 3.0 ppm of reading |

|---|

|

| Repeatability | ± 3.0 ppm of reading |

|---|

|

| Long term output drift | < 0.4% signal loss/month |

|---|

|

| Response Time | t90 < 50 sec. |

|---|

|

| Sensor life expectancy | 3-5 years, normal operating

environment |

|---|

|

| Sensor coverage | 5,000 sq. ft., max 10,000 sq. ft.

(465 m2, max 930 m2),

under “ideal conditions” |

|---|

|

| Installation Location | |

|---|

|

| Mounting height | 5 to 6 ft. (1.5-1.8 m) above floor |

|---|

|

| Type of Control | |

|---|

|

| General | Four-stage (S1 to S4) control,

assignable up to two (2) binary/

relay, horn/audible alarm, and

24 VDC / 50 mA switched

outputs, i.e. low-high stage for

relay output, horn / audible alarm

and switched 24 VDC at any

stage for remote alarming |

|---|

|

| Analog input | One (1) 4-20 mA, for additional

remote sensor, load < 55 mA /

200 Ω, reverse polarity protected |

|---|

|

| Analog reading | Current and mean (average)

value |

|---|

|

| Stage level/setpoint | Field adjustable over full range,

four (4) stages (S1 to S4) per

analog input, assignable to

current or mean (average) value |

|---|

|

| - hysteresis/ switching differential | Selectable for each sensor point |

|---|

|

| Digital input | One (1); can be assigned to any

relay (R1, R2). |

|---|

|

| - application | Remote audio/visual alarm reset

or override function |

|---|

|

| Relay outputs (R1, R2) w/ status LEDs | (1) SPDT (R1), and (1) SPST-NC

or SPST-NO (R2),

jumper selectable |

|---|

|

| Contact rating | 30 VAC/VDC, 0.5 A, max. |

|---|

|

| - each stage level (S1-S4) | Assignable to any relay |

|---|

|

| - sensor fail-safe | Assignable to any stage level |

|---|

|

| Time delay switching | Selectable for make and brake of

each sensor point (SP1 to SP2)

0‑9,999 seconds |

|---|

|

| Analog output | One (1),

(0)4‑20 mA, load < 500 Ω;

(0)2-10 VDC, load > 50K Ω;

jumper selectable;

polarity protected,

assignable to low, high or

averaging of sensor inputs |

|---|

|

| VDC switched output | One (1) 24 VDC, 50 mA max |

|---|

|

| Audible alarm | 83 db @ unit, enabled or

disabled, selectable; assignable

to stage level S1, S2, S3 or S4 |

|---|

|

| Alarm acknowledgment | Menu-driven and system reset

function for latched relays |

|---|

|

| User Interface | |

|---|

|

| Keypad type | Refer to illustration “Keypad User

Interface” |

|---|

|

| Touch buttons | Four (4) |

|---|

|

| Status LED’s | Four (4), for system on,

stage status, and failure |

|---|

|

| Digital display | Liquid Crystal Display (LCD),

two lines, 16 characters per line,

1 digit resolution |

|---|

|

| - unit display | Menu selectable, per sensor;

ppm, %v/v, %LEL, °F or % RH |

|---|

|

| Environmental | |

|---|

|

| Permissible ambient | |

|---|

|

| - working temperature | 14°F to 122°F (-10°C to 50°C) |

|---|

|

| - storage temperature | 23°F to 86°F (-5°C to 30°C) |

|---|

|

| - humidity | 15 to 95% RH, non-condensing |

|---|

|

| - working pressure | Atmospheric ± 10% |

|---|

|

| Physical | |

|---|

|

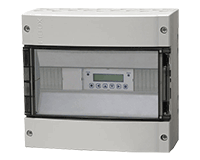

| Enclosure (panel) | |

|---|

|

| - material | Polycarbonate,

UL 94-HB, fire-retardant |

|---|

|

| - conformity | UL 50 standards |

|---|

|

| - color | Light gray |

|---|

|

| - protection | NEMA 4X (IP65) |

|---|

|

| - installation | Wall (surface) mounted,

or single gang electrical box |

|---|

|

| Dimensions (H x W x D) | 5.12 x 5.12 x 2.95 in.

(130 x 130 x 75 mm) |

|---|

|

| Cable entry | 3 holes for 1/2 in. conduit for wall

(surface) mounting and 1 hole on

back side of base plate for single

gang electrical box mounting |

|---|

|

| Wire connection | Terminal blocks,

screw type for lead wire |

|---|

|

| Wire size | Min. 24 AWG (0.25 mm2)

Max 14 AWG (2.5 mm2) |

|---|

|

| Wire distance | Max. loop resistance 450 Ω

(= wire distance plus controller

input resistance) |

|---|

|

| Weight | 0.6 lbs (0.3 kg) |

|---|

|

| Approvals / Listings | |

|---|

|

| - unit rating | NRTL Perf Tested & Certified

Conforms to STD ANSI/UL 2075

City of Los Angeles

CE

VDI 2053, C-No. 418791

EMV-Compliance 2004/108/EWG |

|---|

|

| - relays (R1-R2) | UL Recognized, E41515

CSA, C22.2 No. 0, No. 14

(File No. LR31928) |

|---|

|

| - enclosure | UL Listed, E208470

CSA Certified, E208470 |

|---|

|

| Warranty | Two years material and

workmanship, 12 months normal

exposure for sensor element |

|---|