Why Are Gas Detection Systems So Expensive?

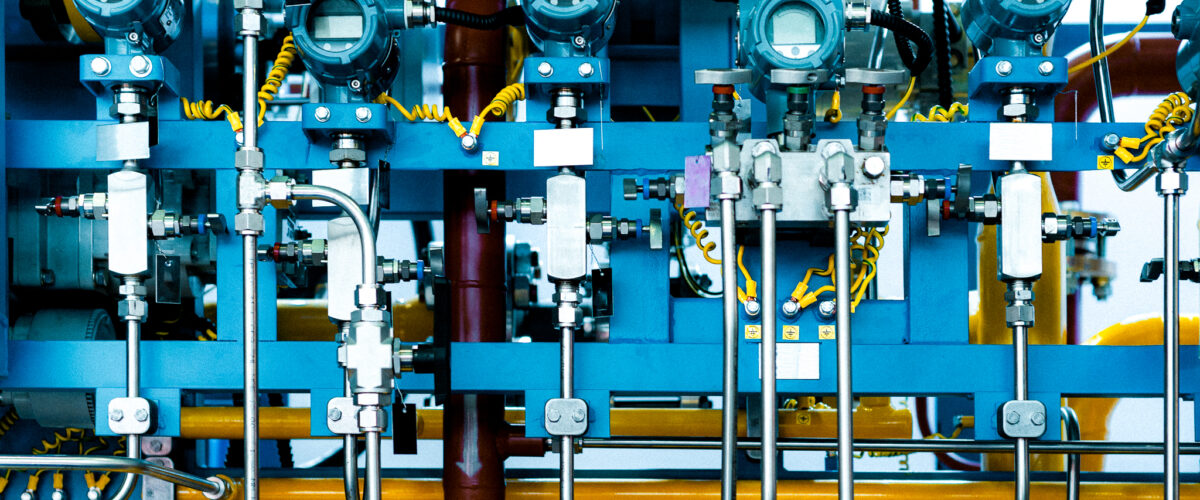

If you have ever received a quote for a gas detection system and felt some sticker shock, you are not alone. Gas detectors are not like fire alarms or basic safety devices. They are precision-built instruments that must identify dangerous gases in real time and in challenging environments.

In many cases, the sensors themselves are the single largest cost. They need to be accurate, rated for the right conditions, and certified for compliance. Once you add the control panels, alarms, installation work, and ongoing maintenance, the price starts to make sense.

Advanced Features and Configurations That Influence Gas Detector Cost

Gas detection systems must meet strict certification and calibration requirements. They are expected to detect hazardous gases with accuracy, day after day, in environments that may be hot, cold, damp, or potentially explosive.

Sensors

Different gases require different sensor technologies such as electrochemical, catalytic bead, MOS/semiconductor, infrared (NDIR), photoionization, and partial pressure. An infrared fixed-point sensor typically costs about $1,750, but the price can range from $1,250 to $3,000 depending on the target gas, whether it is explosion-proof, and the communication features. Electrochemical sensors usually last 2–3 years, while infrared sensors often run 10 years before parts need replacement. Sensor elements typically cost $250 to $750 each.

Controllers & Control Panels

Controllers gather data from multiple sensors and trigger alarms, ventilation, or equipment shutdowns. A standard control panel may cost $1,500 to $5,000, while fully custom PLC-based systems with specialized displays and software can exceed $50,000 to $100,000.

Alarms & Notification Systems

Visual alarms, audible alarms, network notifications, and integration with emergency systems all add cost. If the installation is in a Class I Div 1 hazardous area, explosion-proof horns and strobes are required and these cost more than standard equipment.

Custom System Design vs. Generic Packages

Off-the-shelf gas detection kits are less expensive and quicker to install, but they have limited flexibility. Custom systems are designed for specific gas hazards, facility layouts, and regulatory requirements. This means higher upfront cost but a better long-term fit.

We have designed simple two-sensor systems for under $5,000. At the other end of the spectrum, we have delivered multi-gas, fully integrated installations costing $65,000 to $200,000, especially when working with gases such as hydrogen cyanide (HCN) or hydrogen chloride (HCl).

Integration with Modbus, BACnet, cloud dashboards, or enterprise systems like SCADA requires additional engineering and installation time, but it also allows for easier expansion in the future.

Long-Term Value in Safety and Liability Reduction

Cutting corners on gas detection often leads to expensive mistakes. We have seen clients choose low-cost systems that did not meet certification requirements, only to have them rejected by the safety team or local authority. The money spent on those systems was completely wasted.

A well-designed system can prevent equipment damage, production shutdowns, or explosions. For one aerospace client, we built a custom sampling system for furnace exhaust gases. It included a cooling system, compressed-air sampling, and automated valve sequencing. The cost was significant, but it allowed them to safely monitor highly toxic and flammable gases and avoid a major incident.

Total Cost of Ownership: Looking Beyond the Initial Price

The purchase price is only part of the story. You should also consider:

- Sensor replacements every 2–3 years (or 10 years for infrared sensors)

- Calibration services

- Installation complexity such as hazardous classifications, long conduit runs, or electrical interference

- Special materials for food processing, MRI labs, or corrosive environments

Choosing the right system from the start helps control costs later. For example, a daisy-chained Modbus setup uses less wiring than individual analog runs, and systems with remote diagnostics can reduce the number of service visits.

FAQs

Why are gas detectors more expensive than other safety systems?

They use advanced sensor technologies, require hazardous-area certifications, and often integrate with complex building or industrial systems.

What features or configurations affect pricing?

Gas type, sensor technology, explosion-proof ratings, control panel complexity, integration requirements, and the installation environment all influence cost.

How can I control costs without sacrificing safety?

Work with an experienced specialist who understands your hazards, regulations, and facility layout. Avoid overbuying features you will not use, but do not compromise on certifications, expandability, or integration capability.

Get Expert Help Choosing a Gas Detection System That Fits Your Budget

The cost of a gas detection system depends on many factors, from the sensors and control panels to the installation and long-term maintenance. The right system reduces risk, supports compliance, and protects your team for years to come.

Contact Hawk Equipment Services today to design a gas detection system that meets your needs and your budget.