5 Questions to Ask Before Buying Gas Detection Equipment

Choosing the right gas detection device is more important than most people realize. The wrong choice can leave gas leaks undetected, cause costly downtime, or even put your team out of compliance. Gas detectors, whether fixed or portable gas detectors, are essential safety tools.

Before a gas detection installation, it helps to step back and ask the right questions. Doing so ensures you get equipment that is reliable, compliant, and cost-effective for the long haul.

1. What Are the Vendor’s Capabilities and Experience?

Not all vendors are the same. Some specialize in gas detection devices, while others treat it as just one more product line. Hawk sees the behind-the-scenes details that never make it into a spec sheet, including how different brands perform in the field, whether tech support is responsive, and how quickly parts can be delivered.

A common mistake we see is customers buying equipment marketed as “easy” or “low-maintenance.” In reality, all detectors require proper calibration and care to stay accurate and compliant. The right vendor will explain that clearly and help you plan for ongoing support.

2. What Warranty and Service Agreements Are Available?

A strong warranty protects you if sensors or electronics fail early. Just as important are service agreements that cover calibration, bump testing, and emergency support.

When a gas detection device goes down, speed matters. Ask vendors how quickly they can respond and whether they already have the tools, gases, and reporting systems in place to get your equipment back online. Hawk maintains calibration supplies and trained staff, which saves clients time and reduces costly delays.

3. What Are the Calibration and Maintenance Requirements?

Every gas detection meter or portable gas monitor needs regular calibration. Manufacturers often recommend bump tests before each use and full calibrations every few months. The reality in the field is that very few end-users follow this schedule.

For a small system or portable device, supplies alone can cost $1,000 to $2,000 per year. That does not include training, reporting, or time spent by your staff. Hawk provides calibration as part of our service, with trained technicians and the right gases on hand. This keeps devices accurate and compliant without adding hidden labor costs.

4. Is the System Compatible with Your Facility or Automation Systems?

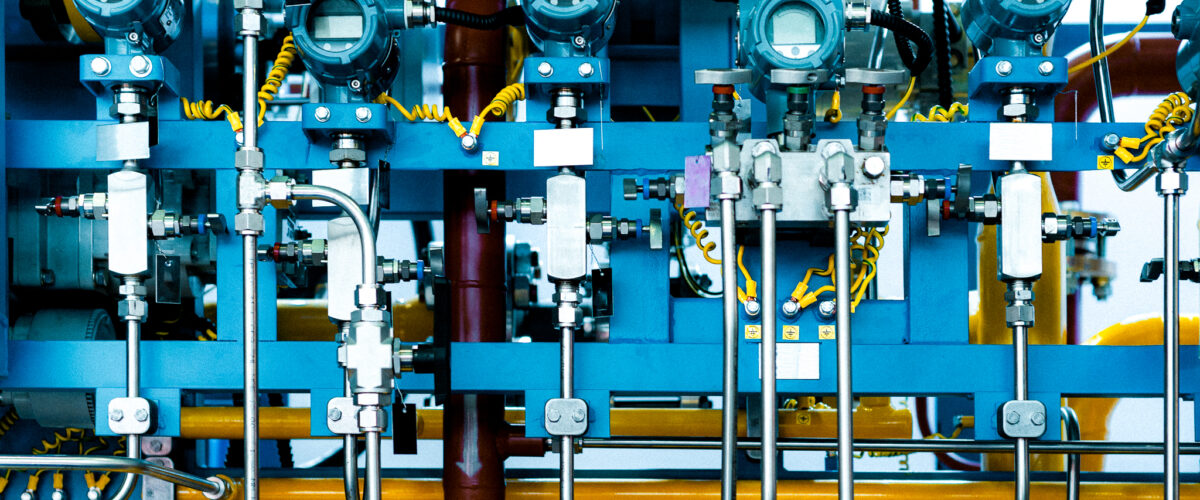

Your detectors should integrate smoothly with your existing safety or automation systems. Hawk regularly ties detectors into BAS, PLC, and SCADA systems using the communication method that makes the most sense for the site.

We often recommend dry contacts for connecting to alarms or ventilation equipment, 4–20 mA signals for PLC systems, and BACnet for building automation. The goal is to use what fits best for your operations so alerts flow to the right place without interruption.

5. What Is the Total Cost of Ownership?

Looking only at the sticker price is a mistake. A portable gas detection meter might cost $500 to $5,000. A fixed system starts around $1,500 and can scale to hundreds of thousands depending on facility size.

The long-term cost of ownership includes calibration, maintenance, sensor replacement, and software updates. Higher-quality systems often end up costing the same as “budget” models once you add service and upkeep. Cheaper, unreliable devices can lead to downtime, false alarms, and compliance issues that cost far more than the equipment itself.

Additional Considerations Before You Commit

Check that the detectors meet OSHA, NFPA, and UL standards. Buying sensors with the wrong certifications can be a costly mistake, especially in industries handling explosive gases. For example, facilities that require Class 1 Div 1 rated equipment cannot safely use lower-cost NEMA 4X sensors.

Hawk has also prevented clients from purchasing uncertified overseas equipment that would have been rejected by inspectors. Asking these questions upfront can save thousands in wasted purchases.

How Hawk Helps You Make the Right Choice

Hawk specializes in guiding customers through every stage of choosing and installing gas detection equipment. We provide expertise that covers vendor evaluation, calibration planning, integration, and compliance documentation.

Whether you need a portable gas meter or a complete gas detection installation, Hawk helps you avoid costly mistakes and ensures your system is built to last. Contact our team today to discuss your project and choose equipment with confidence.