Avoid These Mistakes When Sourcing Gas Detector Equipment

Buying gas detector equipment should feel straightforward, but it rarely is. The biggest sourcing mistakes happen when someone treats detection equipment like a commodity and shops a part number instead of designing for the hazard and the site.

If you want fewer false alarms, fewer surprises during audits, and fewer expensive “do-overs,” these are the mistakes to avoid.

Common Gas Detector Equipment Sourcing Mistakes And How To Avoid Them

Mistake 1: Choosing Based On Price Instead Of Need

Price shopping usually looks smart until the hidden costs show up. One of the most common outcomes we see is a higher rate of DOA units, which turns into delays, rework, and finger-pointing.

The other issue is sourcing gas detection equipment with limited features that block future upgrades. That can force you to replace a panel or sensor family sooner than you planned, even if your hazard profile stays the same.

Real-world cost ranges (ballpark):

- Fixed sensor head (non-explosion-proof): $500–$1,000

- Fixed sensor head (explosion-proof): $950–$2,500

- Small controller/panel: $2,500+

- Larger panel: $4,000–$6,000

- PLC-style solutions: $14,000–$25,000

- Horn/strobe (non-explosion-proof): $200–$500

- Horn/strobe (explosion-proof): $1,200–$2,500

- Calibration gas + regulator kit setup: $650–$1,500

- Site visit: $1,500–$2,000

- Per-sensor calibration/service: $80–$225 each

Those ranges are exactly why “cheapest up front” is not the same as “lowest total cost of ownership.”

Mistake 2: Not Verifying Certifications And Compliance Early

A lot of people assume the device is “certified” because it is sold for gas detection. That is not enough.

Common assumptions we see customers get wrong include ratings and listings like UL 61010-1, UL 2075, Class I Div 1, and SIL ratings. The right requirement depends on the hazard, the environment, and how the system is being used.

The simplest way to avoid this is to treat compliance as part of sourcing, not something you figure out after purchase. This is one reason we push customers to involve a sales engineer early, because the right answer changes with the application.

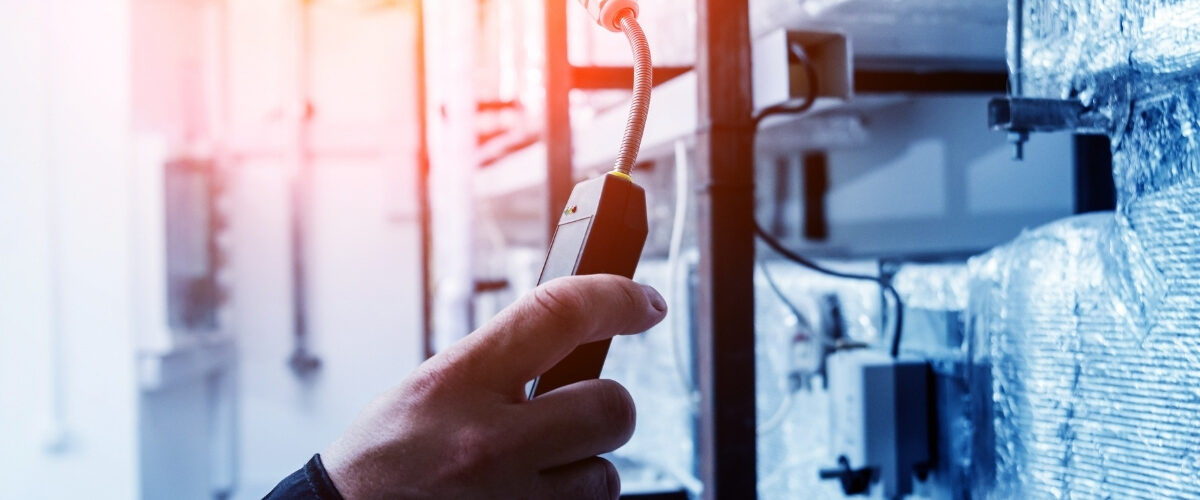

Mistake 3: Ignoring Service And Support Until Something Breaks

Gas detectors are not “install and forget.” If you buy gas detector equipment without a real plan for service, calibration, and parts availability, you are buying downtime later.

Before you source anything, ask about:

- Lead times for sensors, controllers, and replacement parts

- Parts availability and lifecycle expectations

- Engineering support for submittals, layouts, and wiring diagrams

- Access to documentation and the right people when something is not right onsite

A realistic gas detection maintenance plan usually includes calibration every 6 months or sooner. Bump testing can sometimes be done by the customer, but it is less and less frequently required in many programs, depending on site policy and requirements.

Mistake 4: Overlooking Integration Needs

This is one of the most expensive mistakes because it can force a redesign after equipment is already installed.

The classic failure is a panel that does not have the right outputs for the current BMS, or for the BMS the facility will move to later. The fix is simple, but it has to happen at the beginning.

Design for multiple output options from day one. That includes planning for what your BAS or SCADA expects, and how alarms should be routed and displayed.

A good scaling rule is to build in capacity. We often recommend at least 20% spare inputs and 20% spare outputs so the system can grow without ripping out the core.

Mistake 5: Choosing The Wrong Sensor Technology For The Environment

Sensor selection is not just “detect the gas.” It is also about what else is in the air and what your process does day to day.

Here are three common wrong-fit examples we see:

- Catalytic bead LEL sensors in low-level hydrocarbon environments can be poisoned. In some applications an infrared LEL detector is a better choice, but infrared will not cover every gas. For example, IR LEL will not work for hydrogen, so you have to design around the actual flammable risk.

- Portable gas detectors zip-tied in place as a “fixed” solution. Portable gas detectors are made to protect people as they move, not to be permanently mounted and tied into life-safety alarms.

- Residential-grade CO alarms used in life-safety roles. We still see this. It creates serious liability risk, and it can fail you during enforcement or an audit.

A Short Sourcing Checklist That Works

You do not need to be an expert, but you do need a process. Here’s the practical flow we recommend:

- Start with a hazard assessment, what gases, where, and what response time matters.

- Confirm the environment, temperature, humidity, contaminants, and whether it is a hazardous area.

- Verify certifications and listings that match the application, not what someone “thinks” it has.

- Confirm integration signals and alarm behavior, then select panels and sensors that support it.

- Lock in the maintenance plan and parts strategy before the purchase order is cut.

Documentation Customers Should Demand At Purchase And Turnover

This is where good vendors separate themselves from box-shippers. At minimum, customers should require:

- Operations manuals

- A commissioning report

- Fresh calibration on all sensors

- Labels on each sensor showing date calibrated and date due

- A quote for the next recommended routine calibration visit

For audit-proof calibration records, the details that matter most are:

- Dates

- Gas lot numbers

- Pass/fail results

- Gas testing proof

- Calibration certificates

- On-site labeling that matches the records

A Real Example: The “False Co Alarms” Problem

We frequently run into sites with CO sensors installed near lead-acid battery charging areas. Low levels of hydrogen can be present, and if the CO sensor is not properly hydrogen-compensated, the site can get frequent false alarms.

That is a sourcing failure, not a technician failure. The sensor choice did not match the environment.

FAQs

What are the most common gas detector sourcing mistakes?

Buying on price, assuming certifications, ignoring the maintenance plan, and not designing for integration. The last one is especially painful because it can force a redesign after installation.

How can I avoid buying the wrong system?

Start with the hazard and the environment, then work forward into sensor technology, compliance, integration, and service. If you do it in that order, the right system becomes obvious and the long-term cost stays predictable.

What should I look for in a vendor?

Look for a vendor who asks real questions about your application and can produce submittals, layouts, and wiring diagrams. You also want proven parts availability, support that answers the phone, and a clear plan for calibration, documentation, and long-term ownership.

Partner With Hawk For Reliable Gas Detector Equipment

Hawk’s approach to gas detector selection is simple. We start with the hazard assessment and the site conditions, then match equipment to the real-world requirements, including compliance, integration, and maintainability.

We are not trying to sell you the cheapest device. We are trying to make sure the gas detection system works when it matters, and that you can prove it with documentation afterward.

If you want help sourcing gas detector equipment that fits your application and holds up long-term, contact Hawk today for support from upfront design to commissioning and ongoing service.